|

View Poll Results: Block color?!

|

|

Semi-gloss black

|

|

5 |

100.00% |

|

Green "Metallics" *pics of can posted*

|

|

0 |

0% |

|

Cummins beige

|

|

0 |

0% |

|

Purple

|

|

0 |

0% |

|

Cast Iron

|

|

0 |

0% |

|

Metallic Gold

|

|

0 |

0% |

|

Paint By Numbers

|

|

0 |

0% |

07-22-2010

07-22-2010

|

#1

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

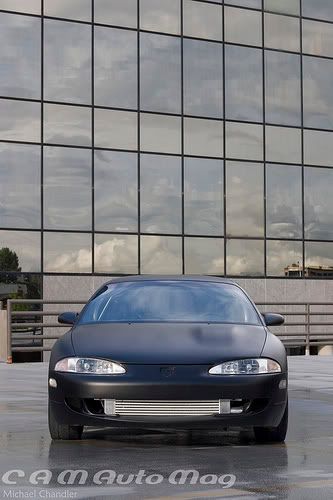

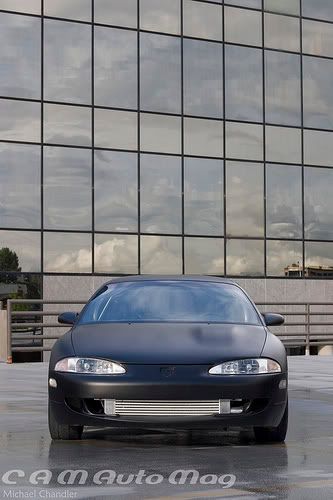

95 Talon TSi AWD

Last edited by DSMINMN; 11-30-2014 at 10:58 PM..

|

|

|

07-22-2010

07-22-2010

|

#2

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

Re: 95 Talon TSi AWD

What needs to be done follows:

Key made for the doors, A LOT of body work, a new paint job (same color *SIGH*..), interior as well....

And I still need to find out whether to go wingless of buy a factory thumbnail.. Also, I need to figure out the body setup... Stay 2ga Talon or go 2gb Talon. Or maybe do a 2gb Eclipse front with 2gb Talon rear... Along with wheels.... Stay the same or change..

Help me out!

Last edited by DSMINMN; 04-07-2012 at 04:19 PM..

|

|

|

07-22-2010

07-22-2010

|

#3

|

|

Transmission destroyer

Join Date: Feb 2007

Location: Cambridge

Drives: G37, 91 TSi

Posts: 7,150

|

Re: 95 Talon TSi AWD

I say wingless 2gb Talon body. You plan on putting Evo 8 wheels on it like in the pics there too?

__________________

Quote:

Originally Posted by scheides

I swing from the nuts of cold hard data. Anything less is a guess.

|

|

|

|

07-22-2010

07-22-2010

|

#4

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

Re: 95 Talon TSi AWD

Quote:

Originally Posted by goodhart

I say wingless 2gb Talon body. You plan on putting Evo 8 wheels on it like in the pics there too?

|

Yeah, that was kind of the plan... Not 100% though.

Last edited by DSMINMN; 04-07-2012 at 04:19 PM..

|

|

|

07-22-2010

07-22-2010

|

#5

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

Re: 95 Talon TSi AWD

|

|

|

07-23-2010

07-23-2010

|

#6

|

|

It was a auto get over it

Join Date: Apr 2006

Location: rochester mn

Drives: something better then you

Posts: 1,987

|

Re: 95 Talon TSi AWD

why did you take all the rear stuff out.

|

|

|

07-23-2010

07-23-2010

|

#7

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

Re: 95 Talon TSi AWD

Quote:

Originally Posted by twack

why did you take all the rear stuff out.

|

Originaly it was because the atena wasn't picking up any radio stations (no its not the radio because the radio is currently in my GS-T and picks up all radio stations), but then we found out the windshield wiper fluid wasnt coming out anywhere..

And after taking everything out and looking at the wiring to the...are they pumps? on the resivour, the male and female power connectors weren't even connect to one another, and the wiring looks getto rigged on top of that..

Which then led me to just wanting to take out the back seat... And it turns out, the terrible smell from the car was the back seats cusion...

Also, there is a wire that runs from where the headunit is supposed to be to the hatch area, and I was told it was for maybe, a subwoofer box or something? Not even sure, so I might just take that out...

Really, it was because I was bored... Plus now that all that is taken out I can clean it.... And get ride of some of the wires that are under there... Some of which I don't understand are there because they don't connect to anything... Kinda of confusing..

Last edited by DSMINMN; 07-23-2010 at 02:20 AM..

|

|

|

08-05-2010

08-05-2010

|

#8

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

Re: 95 Talon TSi AWD

Last edited by DSMINMN; 04-07-2012 at 04:22 PM..

|

|

|

08-09-2010

08-09-2010

|

#9

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

Re: 95 Talon TSi AWD

BTW, painting the car flate black and getting green HID's.

Last edited by DSMINMN; 04-07-2012 at 04:22 PM..

|

|

|

08-10-2010

08-10-2010

|

#10

|

|

Transmission destroyer

Join Date: Feb 2007

Location: Cambridge

Drives: G37, 91 TSi

Posts: 7,150

|

Re: 95 Talon TSi AWD

Quote:

Originally Posted by DSMINMN

BTW, painting the car flate black and getting green HID's.......

|

Why do a bunch of body work just to paint it flat black?

Green HID's???? What is this? Need For Speed Underground?

__________________

Quote:

Originally Posted by scheides

I swing from the nuts of cold hard data. Anything less is a guess.

|

|

|

|

08-10-2010

08-10-2010

|

#11

|

Join Date: Mar 2005

Location: Blaine, MN

Drives: '91 Automagic

Posts: 13,908

|

Re: 95 Talon TSi AWD

For once, I agree with GH.

Dude pick a real color please, once you have been around cars a bit or maybe age a little you will appreciate a real color on a car, shit you love just a mint stock color DSM.

But its your car so whatever and looks like you have the tools to paint the car whenever u want.

so what are the plan for it after flat black and potentially illegal green headlights.

|

|

|

08-10-2010

08-10-2010

|

#12

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

Re: 95 Talon TSi AWD

Quote:

Originally Posted by goodhart

Why do a bunch of body work just to paint it flat black?

Green HID's???? What is this? Need For Speed Underground?  |

Not my choice... If I had my way, it would be a eletric blue or something nice like that but my dad said flate black because it will hide all the hail damage.

Hahaha, that's funny. Got the idea from a friend of Supa's on here or on mitsu-media.com. He has a flate black Neon with smoked lights, and green HID's. Snce I have to do flate black, seemed ideal.

If everyone on this site want's to come and yank the engine so we can paint the 'bay and take all the needed interior out to paint the jams, oh and the prep worth...you can cover the paint and clear too, that would help.

Just saying...

Last edited by DSMINMN; 04-07-2012 at 04:24 PM..

|

|

|

08-10-2010

08-10-2010

|

#13

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

Re: 95 Talon TSi AWD

Quote:

Originally Posted by DSMINMN

Not my choice... If I had my way, it would be a eletric blue or something nice like that but my dad said flate black because it will hide all the hail damage....

Hahaha, that's funny... Got the idea from a friend of Supa's on here or on mitsu-media.com flate black Neon with smoked lights lights, and green HID's....

If everyone on this site want's to come and yank the engine and take all the needed interior out to paint the jabs, oh and the prep worth...you can cover the paint and clear too, that would help.........

Just saying...

|

Quote:

Originally Posted by turbotalon1g

For once, I agree with GH.

Dude pick a real color please, once you have been around cars a bit or maybe age a little you will appreciate a real color on a car, shit you love just a mint stock color DSM.

But its your car so whatever and looks like you have the tools to paint the car whenever u want.

so what are the plan for it after flat black and potentially illegal green headlights.

|

I want a blue color like the blues used on the new Corvette ZR1s (no, I do not like Corvettes).... I didn't pick flate black, my dad did because he said it would hide the hail damage a little more, and it was either the stock green or flate black... And I hate the stock forest dark green...

Hard intake, filter, FMIC, hard piping, Greddy Type-S BOV (recirculated), different exhaust (3 in' all the way back with test pipe in place of the CAT)... Maybe a built stroker engine some day down the road (a few years)... No, I'm not a ricer either... I'm not going to put neon and crap on it...body kits and all that..

Like I said, if I had the money, and ability, I would paint it another color...

Last edited by DSMINMN; 08-10-2010 at 07:01 PM..

|

|

|

08-10-2010

08-10-2010

|

#14

|

|

It was a auto get over it

Join Date: Apr 2006

Location: rochester mn

Drives: something better then you

Posts: 1,987

|

Re: 95 Talon TSi AWD

how can you hate on vettes? they will blow you out of the water all day long. If you want a color to hide imperfections you want white!!! white will hide imperfections. But black even flat black will show all your imperfections......o and your car will look like shit and after the first month you will be very embarrassed to drive it in public

|

|

|

08-10-2010

08-10-2010

|

#15

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

Re: 95 Talon TSi AWD

Quote:

Originally Posted by twack

how can you hate on vettes? they will blow you out of the water all day long. If you want a color to hide imperfections you want white!!! white will hide imperfections. But black even flat black will show all your imperfections......o and your car will look like shit and after the first month you will be very embarrassed to drive it in public

|

I don't like them because I don't like them... :/

This looks like "shit"?:

|

|

|

08-10-2010

08-10-2010

|

#16

|

Join Date: Sep 2007

Location: Minnesota

Drives: DSM

Posts: 319

|

Re: 95 Talon TSi AWD

Instead of "hiding" hair damage, you could have just repaired it. Flat black cars remind me of my rattlecanned honda many years ago. Not the best memories.

|

|

|

08-10-2010

08-10-2010

|

#17

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

Re: 95 Talon TSi AWD

Quote:

Originally Posted by DSMINMN

I don't like them because I don't like them... :/

This looks like "shit"?:

|

Quote:

Originally Posted by Fran05

Instead of "hiding" hair damage, you could have just repaired it. Flat black cars remind me of my rattlecanned honda many years ago. Not the best memories.

|

LOL Who's got the money? To pay the person to remove the bad dents that my dad/uncle can't remove, paint, etc, etc....

Last edited by DSMINMN; 08-10-2010 at 07:34 PM..

|

|

|

08-10-2010

08-10-2010

|

#18

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

Re: 95 Talon TSi AWD

I guess I have to explain... I'm 15. I own no part of the shop. My dad and uncle own it, 50-50 between the two. I work for them every once and awhile. For example: if they need extra work done I will come and help. Or I'll work on my uncle's project cars and get $10 an hour for about 3 hours... Only $30..

Right now I only have about $100 in un-cashed checks, and about $100 cash in my wallet. That can't pay fro everything the car needs.

Sorry guys, if it was up to me, it would be different, but its not.

Last edited by DSMINMN; 04-07-2012 at 04:25 PM..

|

|

|

08-10-2010

08-10-2010

|

#19

|

|

It was a auto get over it

Join Date: Apr 2006

Location: rochester mn

Drives: something better then you

Posts: 1,987

|

Re: 95 Talon TSi AWD

hate to tell you but that black 2g you just posted isnt flat black. its satin black with a clear coat (possibly a matte). I garuntee someone actually put money into his paintjob. FLAT BLACK wont look decent at all

|

|

|

08-10-2010

08-10-2010

|

#20

|

|

Mitsus for days!

Join Date: Dec 2009

Location: Wadena, MN

Drives: '08 Chrysler 300C

Posts: 1,521

|

Re: 95 Talon TSi AWD

Its a girl's car, and she said it was flate black. We aren't using rattel cans. Were using real paint, then putting a flate clear over it.

I just told my dad to paint it the blue color and he said that $200 isn't going to cover the cost to have the dents removed, and all the supplies.

Last edited by DSMINMN; 04-07-2012 at 04:25 PM..

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

|