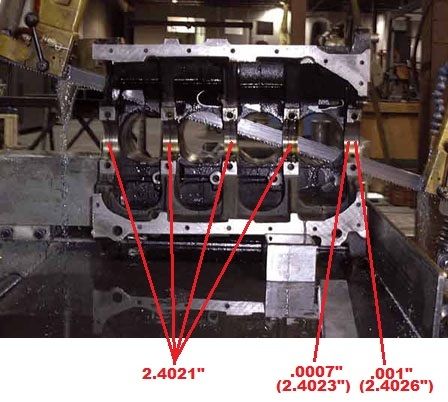

Ran into a little issue with the Evo.III block. This pretty much explains it all.

It's my fault for not spinning the block around on the align hone. Here's a question to machining minded people: what is the best way you've found to take down all the caps on the girdle? How about the block? I've been using a 12" file for the block and our flat sanding block for the girdle. The flat sanding block is so damn short though that it gives me about an inch to move it back and forth. Not to mention I don't have a long enough piece of sand paper to fit under all of the caps.

I'm very close to grabbing a spare block of mine and starting over. Just seems unfortunate to jump ship with the E.3 block being its such a better casting and has oil squirters.

Thanks for any advice in advance!