Some guy on the V forum suggested a kinked line so I checked that, but everything looks good/normal. At the same time I followed the BAP wiring back to the trunk where the fuel pump signal is actually tapped into and there are no shorts or melted spots in the wiring that I could find, it's heavy gauge stuff with a really thick coating, and it's secured really well. I still want to log voltage at the pump just to cover all the angles.

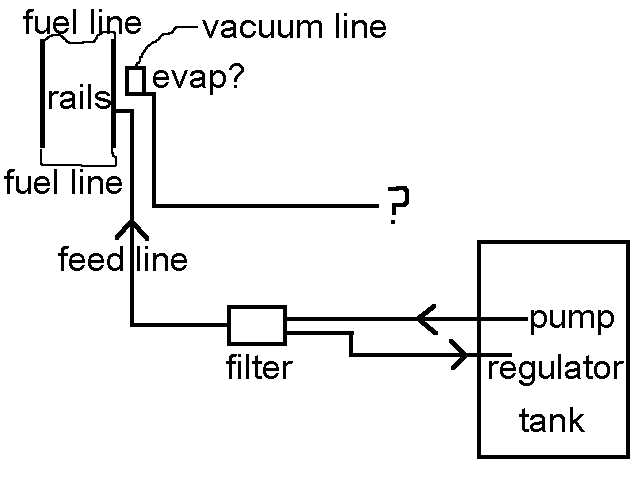

I created a very crude drawing of how I think my fuel system works, it's really weird and I'm not familiar with GM LS motor cars. Anybody on here work with them and can verify this is what's actually happening?

You can see the pump feeds the filter, and there is a return line to the tank and and an output to the rail. What I think this accomplishes is the regulator in the tank can bleed off any post-filtered fuel that the rail doesn't use above 60psi (operating pressure). So at idle the regulator is working hardest, and at full throttle it won't be bleeding off much at all since most will be used by the motor. Is this correct thinking? (Ignore the evap part)

What I thought was weird is that the fuel feed goes into the side of the first rail, and there are two lines connecting the rails, like a big closed loop, not in series as I originally thought.

I took out the rails and injectors tonight thinking maybe something was clogged and found nothing, everything was clean as new. I'm going to see if I can pull out the fuel feed line and check it more thoroughly for kinks and possible clogs.

Edit: just thought of an easier way to verify my pump is working at full capacity (at rest) and the line isn't clogged. I'll hardwire the pump to the battery and see how long it takes to fill a gallon, shouldn't take more than a minute or two if everything is working properly. I believe this would eliminate a flow restriction.