Sounds like a very similar application to my VICS intake manifold controller (mostly identical). It was a decent challenge to set it up, but you want the same thing accomplished, only you'll be using a hobbs switch and I used the AEM, but not much difference.

The issue isn't with the hobbs switch, but with the way the motor that runs the E-cutout needs to be run. It need the polarity reversed, but only needs to be run for +/- 3 seconds, and then shutoff, even though the signal from the switched input is maintained.

I made a few assumptions, but I think your cutout should be run mostly the same way. Only two wires run down to the motor it self right?

I'll agree with Scheides, the way these things are run makes it hard to do things like this.

Also, since it's going to be a challenge to get the cutout run off the hobbs switch, you might want to just add the challenge of triggering it off the throttle position sensor to give the cutout a jump start on opening up. It might only be .2 of a second but having the exhaust bottled up slows down spool-up.

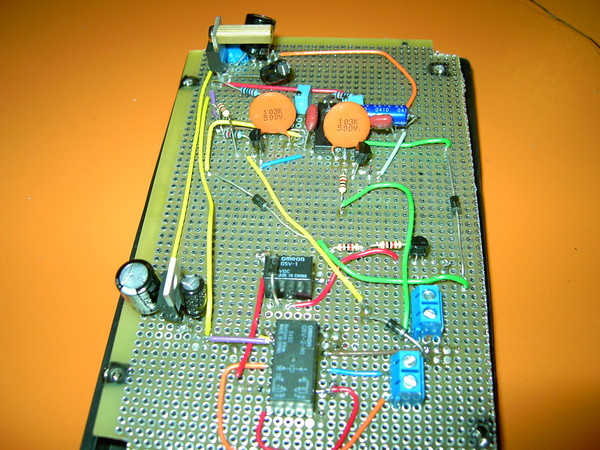

Edit: to show how not simple this is, here is what I built to do what I suspect is the same job.

I'd be willing to build one for you, but I spent ~$100 to build that one and that doesn't include the (lots of) time I put into it.