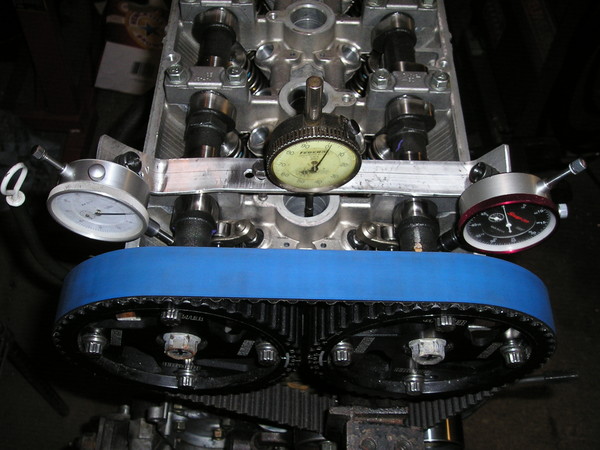

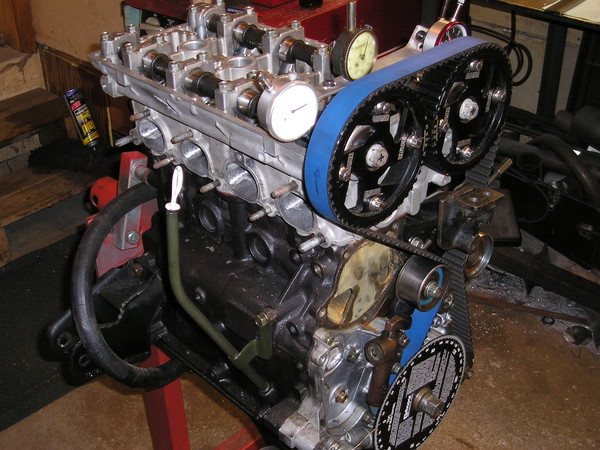

I made a bracket to hold all 3 dial indicators in the right spot so degreeing will be a lot easier and quicker in the future.

Close up at #1 TDC and both valves closed

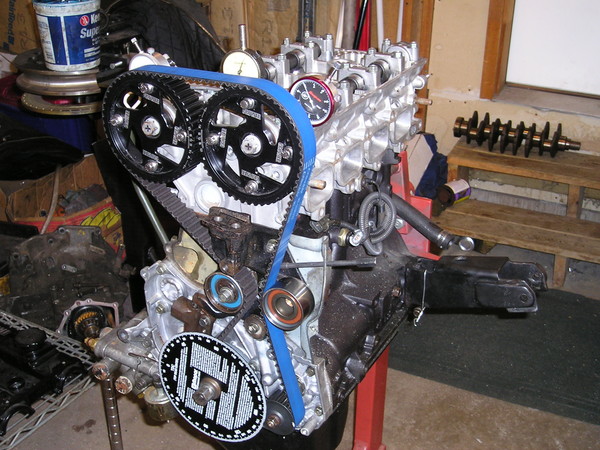

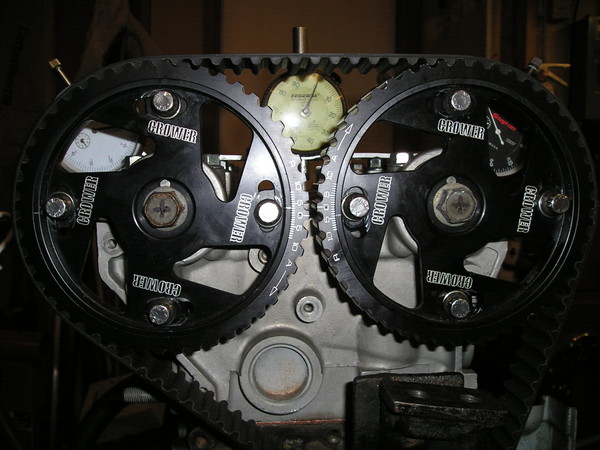

With the Crower cam gears there is no real 0 marks and after all the decking on the block and head this is close to 0, if I run out of adjustment I would need to skip the belt 1 tooth either way on the intake and exhaust.

As it sits right now I can retard the cams a lot, but I do not have hardly any room for advancing the cams, the intake cam is close to hitting the piston when its at 0 and I have the intake retarded 8 deg and the exhaust retarded 6 deg (crank degrees). I know how close the valves are to the piston so I will play around with the cam gears on the engine dyno and see what it likes. I am looking at making the lob seperation higher then it is on the cam card and higher then it was before to help make power up top. Before the lobe seperation was about 104 deg and with were the cams sit now that number is about 110 deg.

Here is a link to the cam card:

http://www.crower.com/misc/cam_spec/...15-2&x=36&y=11

~John